BIW means Body in White. It is one of the most important stages in car manufacturing. For mechanical engineers who want a career in the automotive industry, understanding BIW basics is very important.

What Is BIW

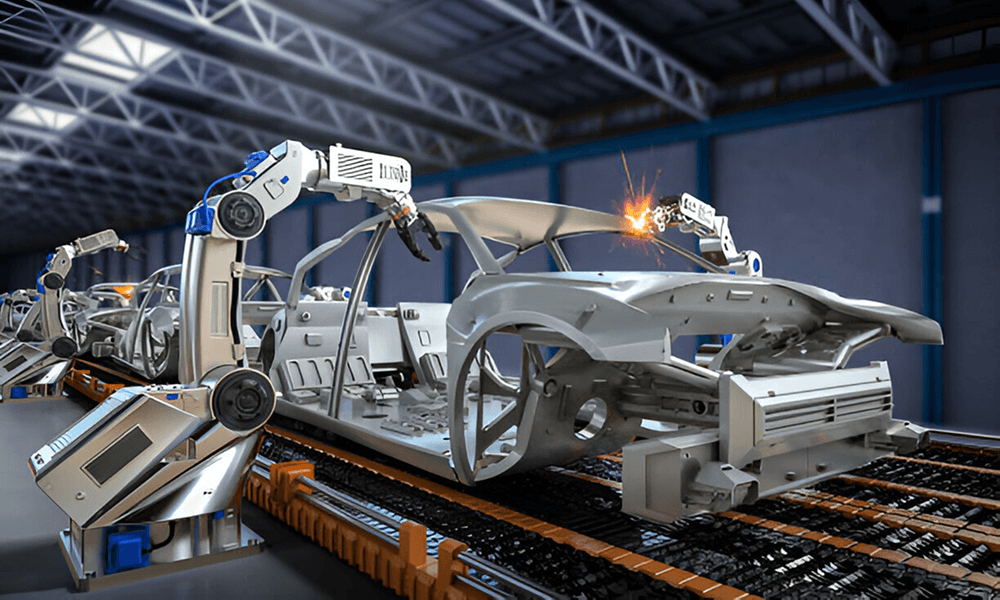

BIW is the stage where the car body is made using sheet metal parts. These parts are joined using welding before painting, interior fitting, or assembly of other components. At this stage, the car body looks white or metallic, so it is called Body in White.

Why BIW Is Important

BIW decides the strength, safety, and shape of the car. Good BIW design improves crash performance, reduces weight, and increases vehicle life.

Main BIW Parts

Some common BIW parts are:

-

Underbody

-

Side panels

-

Roof

-

Front and rear panels

-

Pillars like A pillar, B pillar, and C pillar

All these parts are made mainly from sheet metal.

BIW Manufacturing Process

The BIW process includes:

-

Sheet metal stamping

-

Spot welding and seam welding

-

Use of fixtures and jigs

-

Dimensional inspection

Accuracy is very important because small errors can affect final assembly.

Skills Needed for BIW Engineers

Mechanical engineers working in BIW should know:

-

Sheet metal design basics

-

Welding concepts

-

GD and T basics

-

CAD tools like CATIA or NX

These skills help engineers work confidently in automotive companies.

Career Scope in BIW

BIW engineers are required in design, production, and quality departments. Many automotive OEMs and suppliers hire trained BIW engineers with practical knowledge.

BIW is a strong career option for mechanical engineers interested in automobiles. Start with basics, learn industry tools, and practice real-world concepts. Proper training and guidance can help you enter the BIW domain with confidence