Welcome to the Plastic Domain!

The world of engineering design relies heavily on plastics, and understanding this versatile material is a valuable asset for any aspiring engineer. This domain dives deep into the specifics of designing with plastics, considering not just aesthetics but also manufacturability, functionality, and cost.

Design for Manufacturability (DFM) in Action:

Now that you have your plastic choices, focus on designing the phone stand with manufacturability in mind. Here are some key DFM principles to consider:

- Draft Angles: Ensure your design has proper draft angles to facilitate easy part removal from the mold during injection molding.

- Wall Thickness: Maintain consistent and appropriate wall thickness throughout the design to avoid warping or sink marks.

- Parting Lines: Strategically place parting lines where they will have minimal visual impact and allow for efficient mold opening and closing.

- Fillets and Chamfers: Incorporate fillets and chamfers at sharp corners to improve strength and manufacturability.

Use CAD Software to Prototype:

Utilize your CAD skills to create a 3D model of your phone stand. Apply the DFM principles you researched to ensure your design is optimized for manufacturing.

Bonus Challenge:

Think about sustainability! Explore ways to make your phone stand design more eco-friendly. This could involve using recycled plastics or designing the stand for easy disassembly and recycling at the end of its life cycle.

Deliverables:

- A report outlining your chosen plastic materials and their justification.

- A detailed explanation of how you incorporated DFM principles into your design.

- A 3D CAD model of your phone stand with clear annotations highlighting DFM considerations.

- (Optional) A brief explanation of your sustainability considerations for the phone stand design.

Your Future in Plastics:

A career in the plastic domain opens doors to exciting opportunities across various industries:

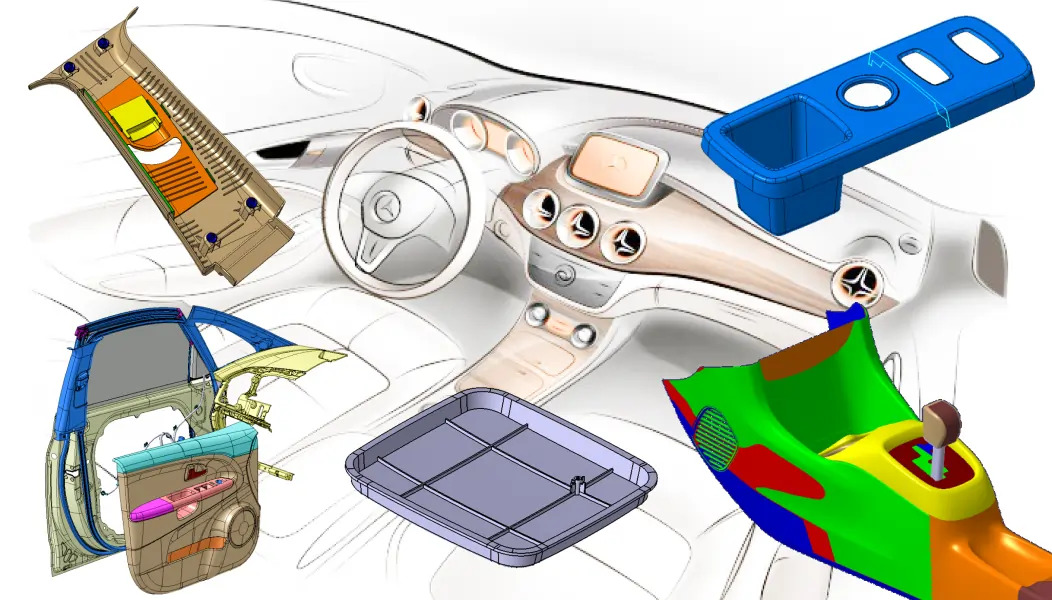

- Consumer Products: From sleek phone cases to intricate toys, your designs could shape the everyday objects people use.

- Automotive: Lightweight and functional plastic components are crucial for modern cars. You could be designing anything from dashboards to aerodynamic parts.

- Medical Devices: Plastics play a vital role in medical equipment. Your expertise could contribute to life-saving innovations.

- Aerospace: Weight reduction is paramount in airplanes. You could design high-performance plastic parts for the next generation of aerospace vehicles.

The plastic domain offers a blend of creativity and technical expertise.

By understanding the material and its manufacturing processes, you’ll be well-equipped to design innovative and functional plastic products that make a real difference.

Become a well-rounded mechanical engineer with the expertise that impresses employers.

Enroll with CADCAMGURU today!