Understanding the Importance of Body in White (BIW) in Mechanical Engineering

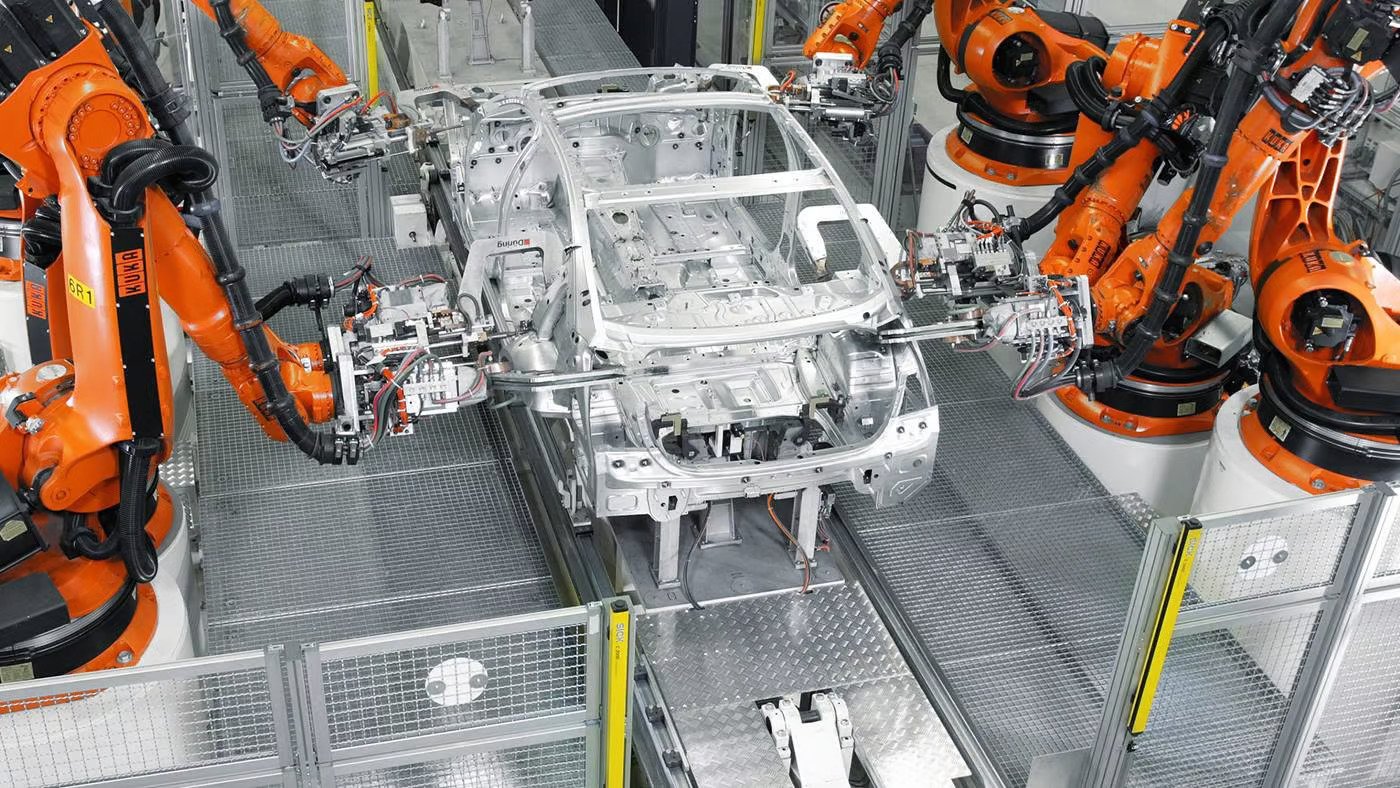

Body in White (BIW) refers to the stage in automotive or aerospace manufacturing where a product’s sheet metal components have been welded or joined together but have not yet received a final finishing. This stage is critical as it forms the structural skeleton onto which all other components such as doors, engine, and interiors are assembled.

Key Elements of BIW:

- Structural Integrity: BIW components must provide structural rigidity and crashworthiness while minimizing weight. Engineers employ advanced materials like high-strength steel, aluminum alloys, and composites to achieve these goals.

- Manufacturing Processes: BIW involves various manufacturing techniques such as stamping, welding, and adhesive bonding. Engineers optimize these processes to ensure dimensional accuracy, strength, and repeatability.

- Design Optimization: Engineers focus on optimizing BIW designs using computer-aided design (CAD) and simulation tools. This ensures that the BIW structure meets performance requirements while minimizing material usage and assembly complexity.

- Integration with Other Systems: BIW components serve as the foundation for other vehicle systems. Integration involves considerations for assembly ergonomics, vehicle dynamics, and ease of maintenance.

Career Opportunities in BIW:

- Design Engineer: Specializes in creating BIW designs using CAD software, optimizing for weight, strength, and manufacturability.

- Manufacturing Engineer: Focuses on developing efficient production processes for BIW components, ensuring quality and cost-effectiveness.

- Quality Engineer: Ensures BIW components meet rigorous standards through testing and inspection processes.

Future Trends in BIW:

- Lightweighting: Increasing use of advanced materials and structural optimization techniques to reduce vehicle weight and improve fuel efficiency.

- Integration of Electronics: Incorporating sensors and electronics within BIW components for enhanced vehicle performance and connectivity.

- Additive Manufacturing: Exploring 3D printing for rapid prototyping and production of BIW components, enabling complex geometries and customization.

Conclusion:

Body in White (BIW) is a foundational domain in mechanical engineering, playing a crucial role in the design, manufacturing, and integration of structural components in vehicles. As technology advances, the BIW domain continues to evolve, offering exciting career opportunities for mechanical engineers interested in automotive and aerospace industries.

Explore BIW CADCAMGURU to unlock your potential in shaping the future of mobility and structural engineering.