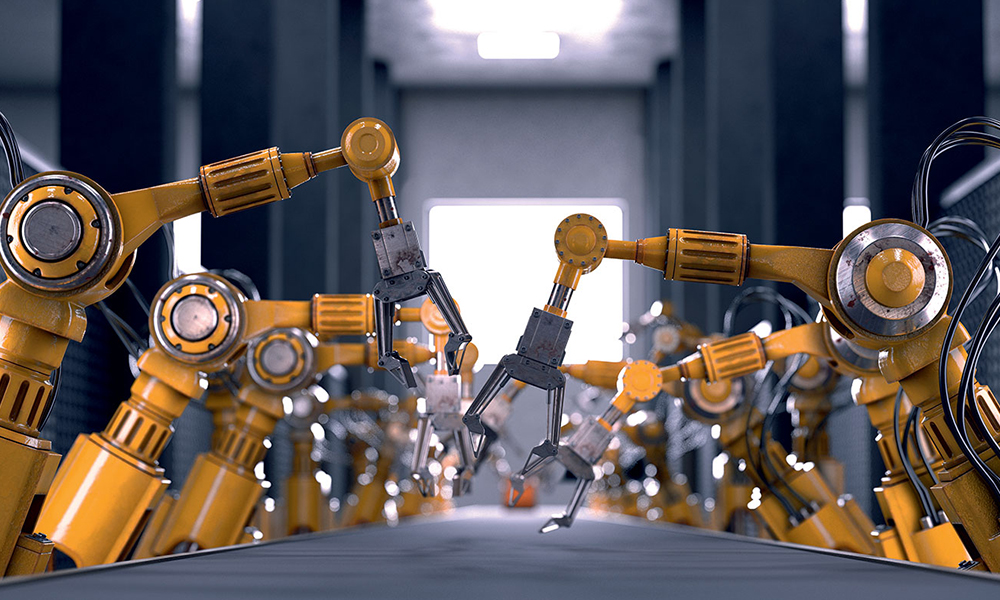

The purpose of automation is to make a machine automatic. Because of automation, human intervention is reduced. Automation is widely used in automobile manufacturing, processed food manufacturing, chemical manufacturing, pharma manufacturing, packing machines, home automation, printing machines, textile machines, furnace and other machines in foundries and so on for a large number of applications.

In manufacturing

Many years ago, when there was no automation, manufacturing was dependant on manually operated machines.

However, it uses PLC, motors, pneumatics, hydraulics, sensors, SCADA, and HMI automation gives advantages like fast speed, high accuracy, high quality, safety, repeatability.

Hence, it is a must for the survival and progress of any manufacturing company.

Benefits of Automation:

Low operating costs

Automated machines can do tasks which are humanly impossible. Due to the efficient and energy-saving abilities of machines, energy bills can also be reduced. More accuracy and reliability results in less wastage and better use of raw material.

Safety against accidents.

By using automation, accidents can be avoided even if the operator commits some mistake unknowingly. High safety is necessary for chemical manufacturing, refineries, foundries and many other sectors. During handling heavy objects safety is necessary for example in the ship construction sector. By using sensors and properly programmed PLC many accidents can be avoided. So employees will have goodwill regarding an employer.

Short delivery time.

Due to the flexibility of programming and high speed of manufacturing, it reduces delivery time. So, a manufacturer can keep commitments given to the customer.

More production due to nonstop working :

Only automated machines can work for 24 hours a day, 7 days a week. So production can be increased.

Quality Improvement :

Using automation, it is possible to achieve quality standards which are not possible manually. For example, a machined component in the aerospace industry must be manufactured to correct specifications, or it will not be suitable for the final assembly. An effective way to do this is by increasing the amount in the factory.

Faster ROI (Return On Investments)

Although it involves high initial costs, it gives faster ROI due to low operation costs, safety, short delivery time and increased production.

Remember, the future belongs to those who embrace innovation.

Investing in Cadcamguru’s Automation courses empowers you to seize the opportunities of tomorrow and shape the connected world of the future.